**The Unsung Heroes of Engineering: Bolts and Nuts**

In our day-to-day lives, we often overlook the tiny but mighty components that hold everything together—bolts and nuts. While they may appear inconsequential, these small parts are essential in countless engineering and construction projects. From your kitchen table to towering skyscrapers, from your car to complex industrial machines, bolts and nuts are everywhere. But what makes these seemingly insignificant pieces so vital across so many fields?

**Basic Design and Functionality**

Bolts are usually crafted from metal, featuring a threaded rod with a flat head, while nuts are hexagonal or circular metal pieces with internal threading. When combined, they create a robust connection through twisting and tightening, enabling them to endure immense forces and pressures. This design allows bolts and nuts to securely fasten objects together, whether it’s joining wooden planks or integrating massive machinery into a seamless unit. Their simplicity ensures stability and safety in all kinds of environments.

**Engineering Applications**

In construction, bolts and nuts are indispensable for connecting steel frameworks. These connections not only support the building's weight but also counteract external stresses like wind and earthquakes. As buildings grow taller, the reliance on bolts intensifies, ensuring structural integrity and safety.

Similarly, in automotive manufacturing, bolts and nuts are fundamental. They link key components such as engines, frames, and body panels, guaranteeing smooth operations and top-tier safety standards. Even minor issues with these connectors can affect a vehicle's overall performance and safety, highlighting their crucial role in the industry.

**Strengths and Challenges**

One of the primary advantages of bolts and nuts lies in their straightforward design, affordability, and ease of use. They are simple to install, maintain, and replace, which facilitates repairs and upkeep. However, as technology advances, there is increasing pressure on these components to handle higher loads and resist corrosion better. Engineers are continually innovating to improve their durability and efficiency, introducing cutting-edge materials and designs.

Furthermore, with the rise of automation and smart systems, traditional bolt-and-nut methods are evolving. New solutions like self-locking nuts and high-strength bolts are gradually replacing older techniques, enhancing connection security and dependability. These advancements reflect the ongoing evolution of engineering practices.

**Final Thoughts**

Around us, bolts and nuts are unsung heroes of engineering, quietly ensuring our safety and comfort. Though they might seem trivial, their contribution to modern engineering and manufacturing is irreplaceable. As we move forward, let’s remember to value these humble components and acknowledge the immense convenience and protection they offer in our daily lives. After all, it’s the small things that often make the biggest difference.

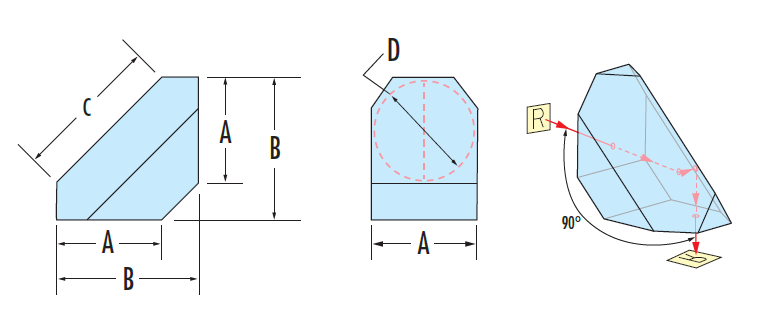

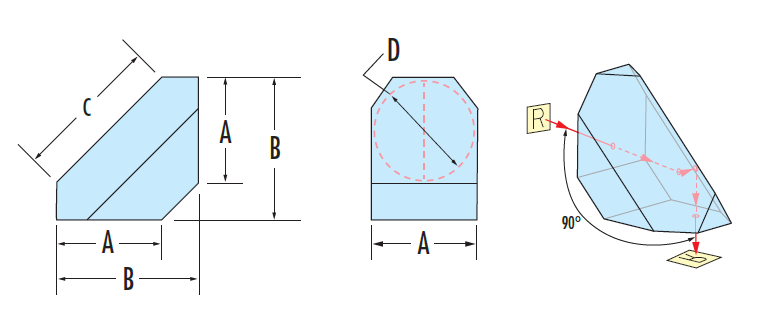

Roof Prism

AMICI reflection prism called also roof prism or right angle roof prism,which deflects the beam through an angle of 90 degree and inverts the image. For this reason,this prism is perfect for erecting images inverted by the objectives.

We supply many types of high precision optical prisms,such as Wedge Prism,Right Angle Prism,rhombohedral prism,Dove prism,Penta prism,pyramid prism,dispersing prism,Reflection prism etc. Each having a particular geometry to achieve the reflections necessary to perform a specific imaging task.Reflecting prisms may invert,rotate,deviate or displace a beam.dispersing prisms produce spectral separation for spectroscopic applications or for tuning a laser output.Wedge prism is commonly used in laser system for eliminating the reflections from the second surface or for beam steering.Irregular-shaped or non-standard size prisms may be available by custom order.

Specification of our Amici roof prism as follow:

*Material BK7 Grade A optical glass,UV fused silica,MgF2,N-SF10 etc.

*Dimension:3-100mm.

*Dimension Tolerance +/-0.2mmÂ

*Beam Deviation Up to 30 arc secondsÂ

*Angle Tolerance Up to 5 arc secondsÂ

*Flatness Up to λ/4 @633nmÂ

*Surface Quality 60/40 scratch and dig,40/20 even better

*Chamfer 0.3mm+/-0.1mmÂ

*Coating: AR coating,HR,PR upon request.Â

Roof Prism,Polished Roof Prisms,Amici Roof Prism,Right Angle Roof Prism

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com